A transformer is an electrical device which, by electromagnetic induction, transforms power between circuits at the same frequency, usually changing the values of voltage and current. Since all source power is generated in 3-phase format, 3-phase transformers play a key role in long distance power distribution, regional grids, local grids, industrial and business facilities.

3-PHASE TRANSFORMER WINDING CONFIGURATIONS

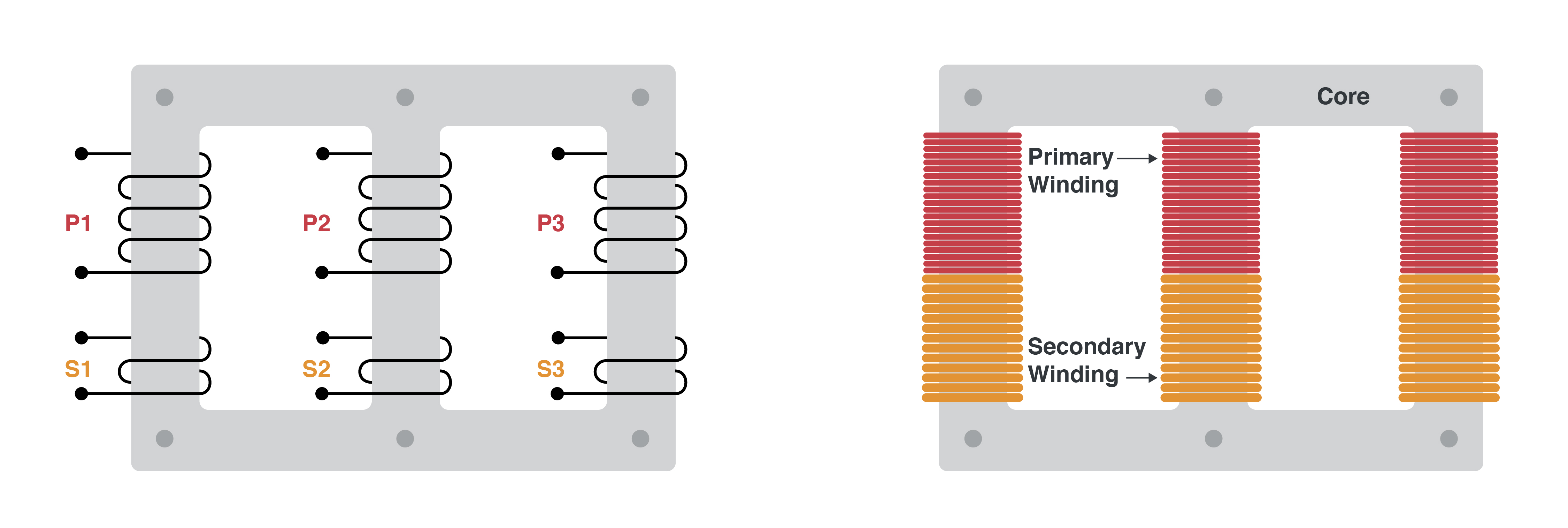

3-phase power transformers are constructed by winding three single phase transformers on a single core. Since copper and the iron core are used more effectively, 3-phase transformers for a given volt-ampere (VA) rating will be smaller, more cost effective, and lighter than three individual single-phase transformers.

Figure 1. Typical physical contact plug and receptacle connectors.

3-phase transformers typically have at least 6 windings- 3 primary and 3 secondary. The primary and secondary windings can be connected in different configurations to meet different requirements. In common applications, the windings are usually connected in one of two popular configurations: Delta or Wye.

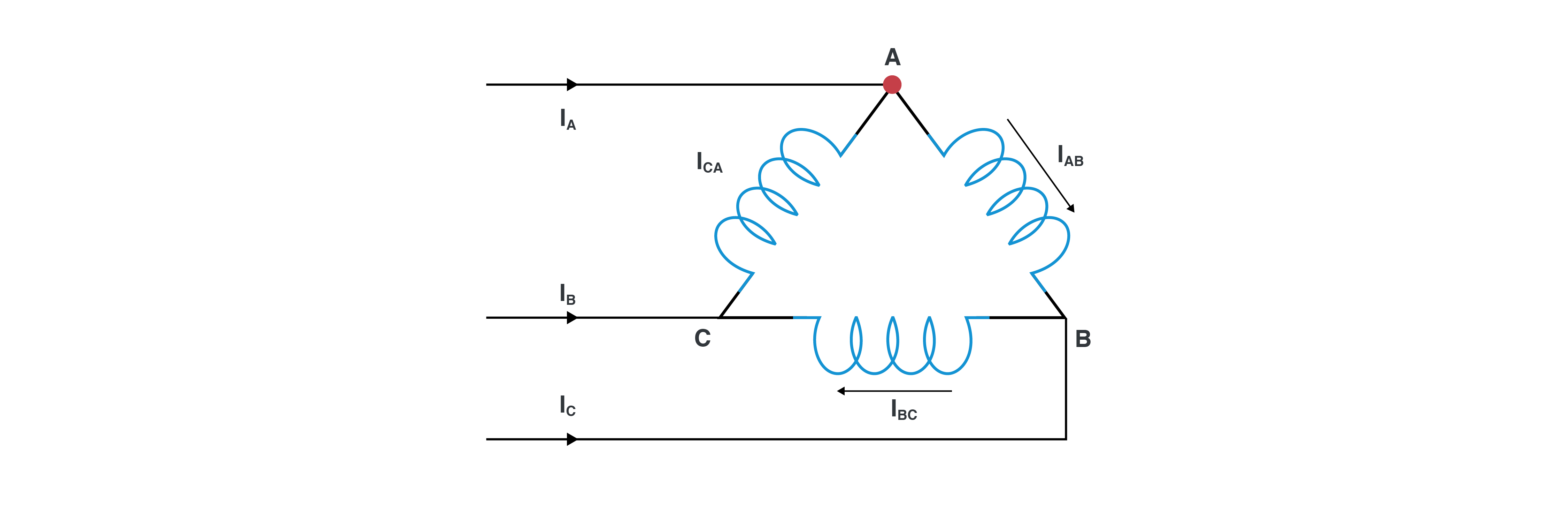

DELTA CONNECTION

In a delta connection, there are three phases and no neutral. An output delta connection can supply a 3-phase load only. The line voltage (VL) is equal to supply voltage. Phase current (IAB = IBC = ICA) is equal to Line current (IA = IB = IC) divided by √3 (1.73). When a transformer’s secondary is connected to large, unbalanced load, the delta primary provides a better current balance for the input power source.

Figure 2. “Delta” connection schematic.

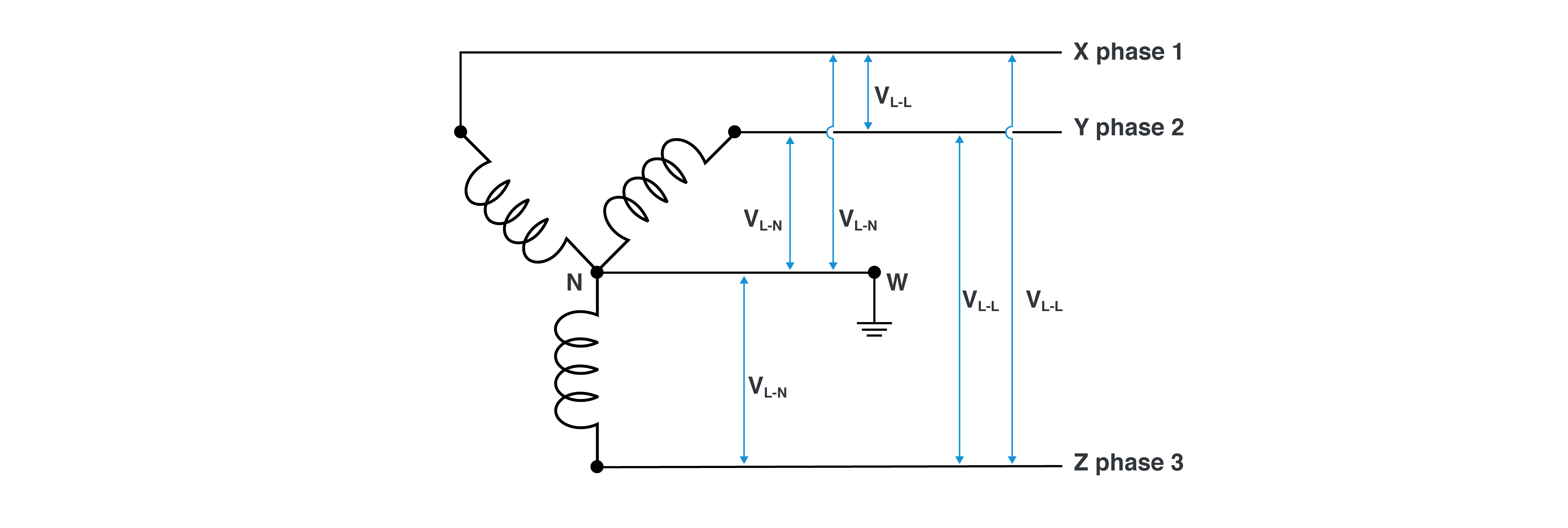

WYE CONNECTION

In a wye connection, there are 3-phases and a neutral (N) – four wires in total. An output of wye connection enables the transformer to supply a 3-phase voltage (phase-to-phase), as well as a voltage for single phase loads, namely the voltage between any phase and neutral. The neutral point can also be grounded to provide additional safety when required: VL-L = √3 x VL-N.

Figure 3. “Wye” connection schematic.

THE FOUR PRIMARY WINDING CONFIGURATIONS

A 3-phase transformer can be connected in four common configurations: Delta-Delta, Wye-Wye, Delta-Wye, and Wye-Delta. Each configuration, distinguished by its primary and secondary winding connections, entails specific advantages and disadvantages, influencing the performance and application suitability of these transformers.

1. DELTA / DELTA (D/D)

D/d Advantages

In a delta-delta transformer (identified as D/d) both primary and secondary windings are connected in the delta configuration. This configuration offers several advantages. If one out of the three coils becomes faulty or disabled, the remaining two undamaged coils can still deliver 3-phase power with a capacity equal to roughly two-thirds of the original transformer’s output.

In cases where the transformer’s secondary is connected to a large, unbalanced load, the delta primary excels at providing a better current balance for the input power source.

One key benefit is the absence of any phase shift between the primary and secondary windings, ensuring a harmonious power transfer. This configuration is often preferred for applications involving low voltage and high current power transmission or when continuity of service must be maintained, especially in the event of a phase fault.

D/d Disdvantages

In this configuration, certain characteristics impact the design and functionality of 3-phase transformers. The high turn count for both primary and secondary windings leads to larger and more expensive coils. This design necessitates additional inter-winding and interlayer insulation. The use of thinner gauge magnet wire increases the cost per pound, and notably, this configuration lacks a neutral connection.

2. DELTA / WYE (D/Y)

D/y Advantages

The primary delta and secondary wye (D/y) configuration stands out for its capability to deliver a three-wire balanced load to the power-generating utility, accommodating various applications seamlessly. This configuration is frequently chosen for supplying power to commercial, industrial, and high-density residential sectors.

This setup is capable of supplying both 3-phase and single-phase loads and can create a common output neutral when the source lacks on. It effectively suppresses noise (harmonics) from the line to the secondary side.

D/y Disdvantages

If one out of three coils becomes faulty or disabled, it can jeopardize the entire group’s functionality, and the 30-degree phase shift between primary and secondary windings may result in greater ripple in D.C. circuits.

3. WYE / DELTA (Y/D)

Y/d Advantages

The Y/d configuration leverages high voltage input, reducing the voltage across individual coils by a factor of √3, resulting in fewer winding turns and reduced insulation. This design can be used as a step-down transformer, primarily at the end of the transmission line. It also includes a grounding wire (neutral) on the power source side.

Y/d Disdvantages

Y/d shares the same potential drawbacks as the D/y configuration—the whole group functionality may become disabled in the event a single coil fails and introducing a 30-degree phase shift between primary and secondary windings, can result in increased ripple in D.C. circuits.

4. WYE / WYE (Y/Y)

Y/y Advantages

Among the four common 3-phase transformer configurations, the Y/y setup is the most cost-effective choice, offering seamless power transmission with no phase shift between primary and secondary windings. Grounding (neutral) wires are available on both the primary and secondary sides, providing versatility to deliver power to both 3-phase and single-phase loads.

Y/y Disdvantages

To ensure optimal performance, single-phase loads need to be balanced as close as possible within this configuration. It’s important to note that the Y/y setup may be more susceptible to passing noise between the power source and the load.

DRY TYPE & LIQUID-FILLED TRANSFORMERS

Depending on power and voltage levels, 3-phase transformers can be divided into two major categories: Dry type transformers that rely on air as cooling medium or Liquid-filled type transformers that utilize oil as a cooling medium.

DRY-TYPE TRANSFORMERS: OPEN FRAME OR CAST-RAISIN COILS

Of the dry-type transformers, there are two main categories:

- Open Frame, featuring exposed resin impregnated core and coils for enclosure installations with electrical ratings of Voltage – up to 1000V and Power – up to 500 kVA.

- Cast-Raisin Coils, where each coil is solidly cast, often in an epoxy mold, with electrical ratings of Voltage – up to 36.0 kV and Power – up to 40 MVA.

LIQUID-FILLED TRANSFORMERS:

Liquid-filled transformers, in contrast, are entirely immersed in special mineral oil within vacuum-sealed metal containers, with electrical ratings of Voltage – 6.0 kV to 1,500 kV and Power – up to 1000+ MVA.

Image 1. Types of transformers.

OPTIMAL OPEN FRAME TRANSFORMERS CONFIGURATION

For open frame transformers when circumstances permit, most industries prefer to use the delta input and wye output for connecting a 3-phase transformer in power distribution applications.

The most common input voltages for delta configurations include 600V, 480V, 415V, 400V, 230V, and 208V. While the most common output voltages for wye configurations are as follows: In Canada: 600V (L-L) and 347V (L-N). For large industrial loads in the US, it delivers 480V (L-L) and 277V (L-N). In the case of small industrial, commercial, and residential loads in the US, the output voltages are 208V (L-L) and 120V (L-N).

Signal Transformer Co. stands as a prominent manufacturer in this domain, specializing in the production of dry-type open frame 3-phase transformers. With more than 50 years of manufacturing transformers, chokes, inductors and custom or modified standard products, Signal Transformer excels in the design and manufacture of cost effective, specialized platforms.

View Bel's selection of Three Phase Transformers

Learn More