ENSURING SAFETY IN MODERN RAIL SYSTEMS

Standards are essential for the design and development of safe and reliable power supply products, especially for transportation systems such as railways. Technical standards address performance, design methodology, verification, implementation, safety, and risk assessment within the context of how they’re going to be used in the real world.

Power distribution systems on trains, no matter their purpose, must be safe and reliable, which means complying with a host of standards, EN 50155 prominent among them. EN 50155 is a European standard that covers electronic equipment used on rolling stock for railway applications, including power supplies. Though the standard was developed by the European Committee for Electrotechnical Standardization (CENELEC), it addresses the global rail market, and is the standard that power supplies for rail applications are often designed and tested to.

Figure 1. Common electronic systems in railway applications.

Trains, including commuter, light rail, freight, and high-speed are already quite popular in places like Europe and Japan, and other regions are increasingly turning to rail to move people and goods more efficiently. EN 50155 has become increasingly important as trains have become more technically advanced from an engineering and passenger experience perspective.

Onboard Wi-Fi, sophisticated climate systems, and complex control and management systems are all placing new demands on electrical systems. This has led to several revisions of EN 50155 as it is continuously updated to assure that standards are keeping up with the growing complexity.

THE PRIMARY STANDARD

EN 50155 covers all of the electronic equipment used for control, regulation, protection, diagnostics, and energy supply in rolling stock applications. The requirements placed on this equipment includes operating conditions, product design and documentation, testing, integration, and software.Power supplies and converters, which are needed to provide clean and stable power to all of electronics found in modern rail applications, fall within the scope of the standard. The key concerns of power supplies in the rail market include supply voltage variation, operating temperature, shock and vibrations, electromagnetic compatibility, and reliability.

REFERENCED STANDARDS

Standards don’t exist in proverbial silos, and EN 50155 is no different. It references many other standards that often deal with more specific issues. Some of those standards that especially apply to power supply design include:

EN 45545-1: This standard concerns fire safety and specifies materials, construction, and testing required to mitigate fire hazards in railway applications.

EN 50121-3-2: This standard addresses electromagnetic emissions and immunity for railway applications. It aims to ensure that equipment does not interfere with nearby devices and is immune from external interference.

EN 61373: This standard outlines shock and vibration requirements for electronic equipment and power supplies used on rolling stock for railway applications, which are rigorous for any system operating in rugged environments. For the purposes of the EN 61373, systems are categorized as carriage-mounted, bogie-mounted, or axle-mounted.

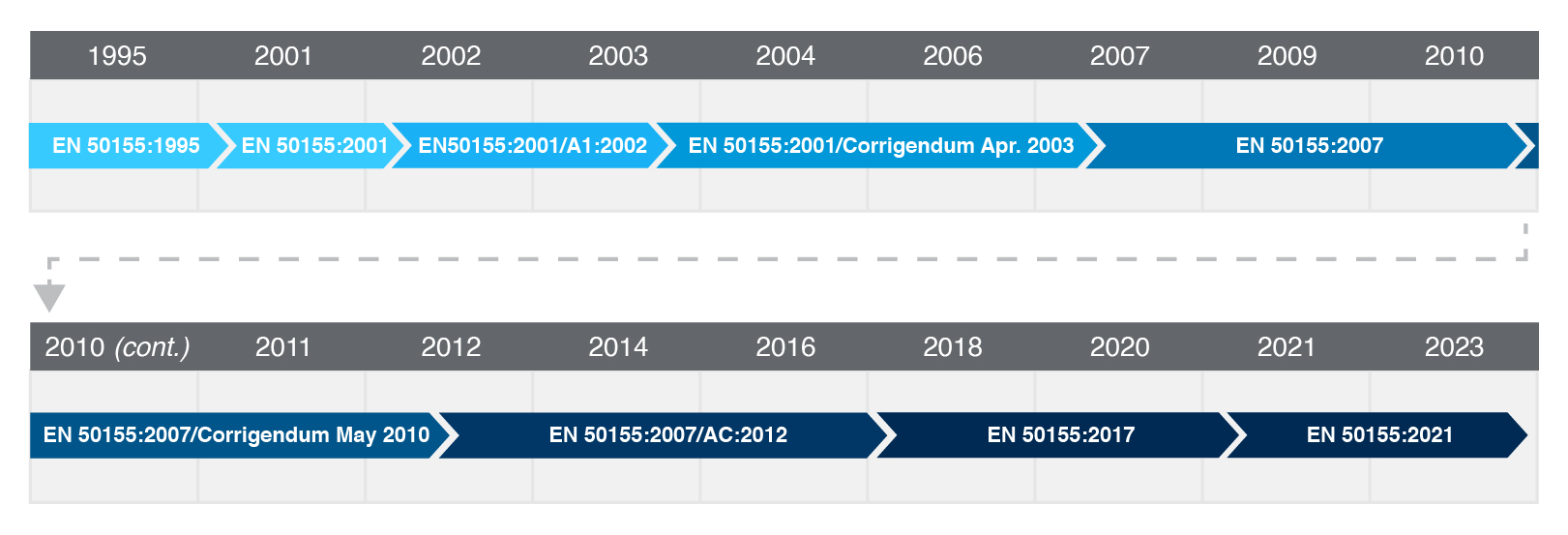

THE EVOLUTION OF EN 50155

As power supply technology has evolved, railways have modernized, and safety requirements have changed, EN 50155 has undergone several revisions since its first publication in 1995 to keep pace.

Figure 2. Timeline of updates and revisions to EN 50155.

The first revision came in 2001 and included new requirements for safety management. It also clarified and strengthened existing requirements.

A big update occurred in 2007 and included the addition of three test categories:

Type tests: Verifying a product meets specified requirements.

Routine tests: Verifying a product meets specified requirements after manufacturing process.

Investigation tests: Determine performance outside of specified requirements.

Testing provisions in the update require that the user shall identify any tests subject to agreement at the time of tendering, while the manufacturer is required to provide a test plan listing all the tests to be performed and their specifications. The equipment is not allowed to malfunction or produce a performance which is outside its specification, as per the 2007 update, which also advises only those tests which are necessary must be carried out as some tests may be costly.

Notable changes in 2017 include the addition of a new reliability test, a rapid temperature variation test, while definitions and illustrations of test conditions were further clarified to allow for more accurate experimentation.

The most notable update in 2017 was a move to six operating temperature classes, shown in Table 1. The default level is OT3. This update also added responsibility with equipment manufacturers and end-users to define operating temperatures for equipment and determine relevant constraints.

Table 1. Operating temperature classes introduced in EN 50155:2017.

| Operating Temperature Classes | ||

| Temperature Class | Temperature Range | Operating Temp. Classes |

| OT1 | -25°C to +55°C | passenger and driver compartments |

| OT2 | -40°C to +55°C | |

| OT3 | -25°C to +70°C | equipment in technical cabinets |

| OT4 | -40°C to +70°C | |

| OT5 | -25°C to +85°C | special applications |

| OT6 | -40°C to +85°C | |

There is also more flexibility around the length of useful life of all equipment – previously it was 20 years, but as of 2017 there are five classes, beginning with five years. However, level 4 is the default, unless otherwise specified.

Table 2. Useful life classes introduced in EN 50155:2017.

| Useful Life Class | |

| Life Class | Useful Life |

| L1 | 5 years |

| L2 | 10 years |

| L3 | 15 years |

| L4 | 20 years |

| LX | Special |

In 2021, a third performance criterion was added, outlining allowable degradation in the event of a test or environmental disturbance, and stipulating the loss of significant stored data is not permitted. EN 50155:2021 also outlines which type of battery voltage supply systems are permitted.

EN 50155 AND ITS RELEVANCE TO POWER SUPPLIES

Power supplies for any type of equipment always influence the design and development of products they’re going into. Standards such as EN 50155 are especially relevant where there are not only stringent performance requirements, but also public safety concerns.

The EN 50155 standard applies to many different aspects of electronic equipment, including installation, control, regulation, and protection. All this equipment is integrated into complex systems, operating in complex real-world environments.

There are five areas that are crucial when designing power supplies for railway rolling stock equipment.

1. SUPPLY VOLTAGE:

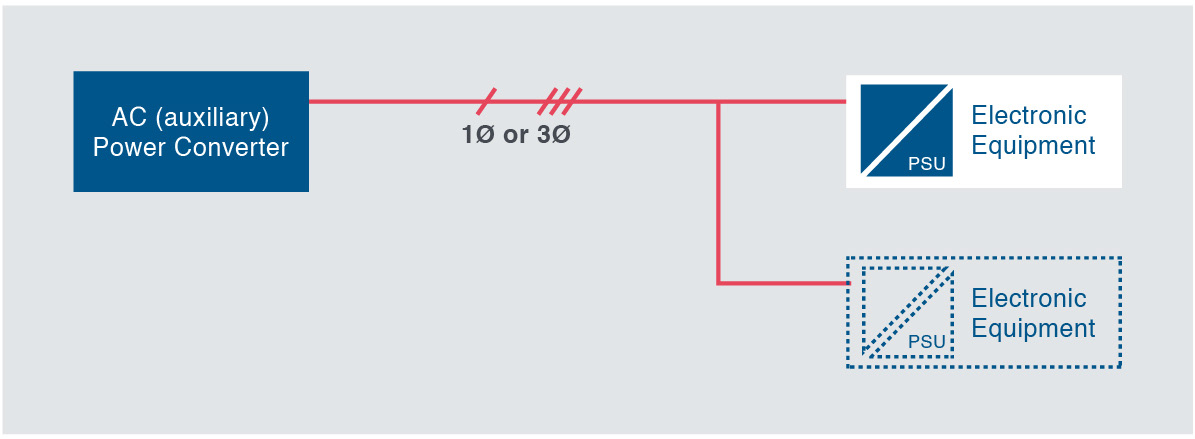

There are several ways that power may be supplied to a railway system, but will be either an AC or DC supply systems. DC power comes from battery supply systems and is what EN 50155 primarily focusses on. Ac power can come from auxiliary power converters, overhead lines or a third rail and are covered in EN 50533:2011 and EN 50163:2014 respectively.

Figure 3. AC supply system example.

For battery supplied DC systems the primary concerns are the battery voltage range, transient voltages, supply voltage interruptions, supply changeover, and DC ripple factor.

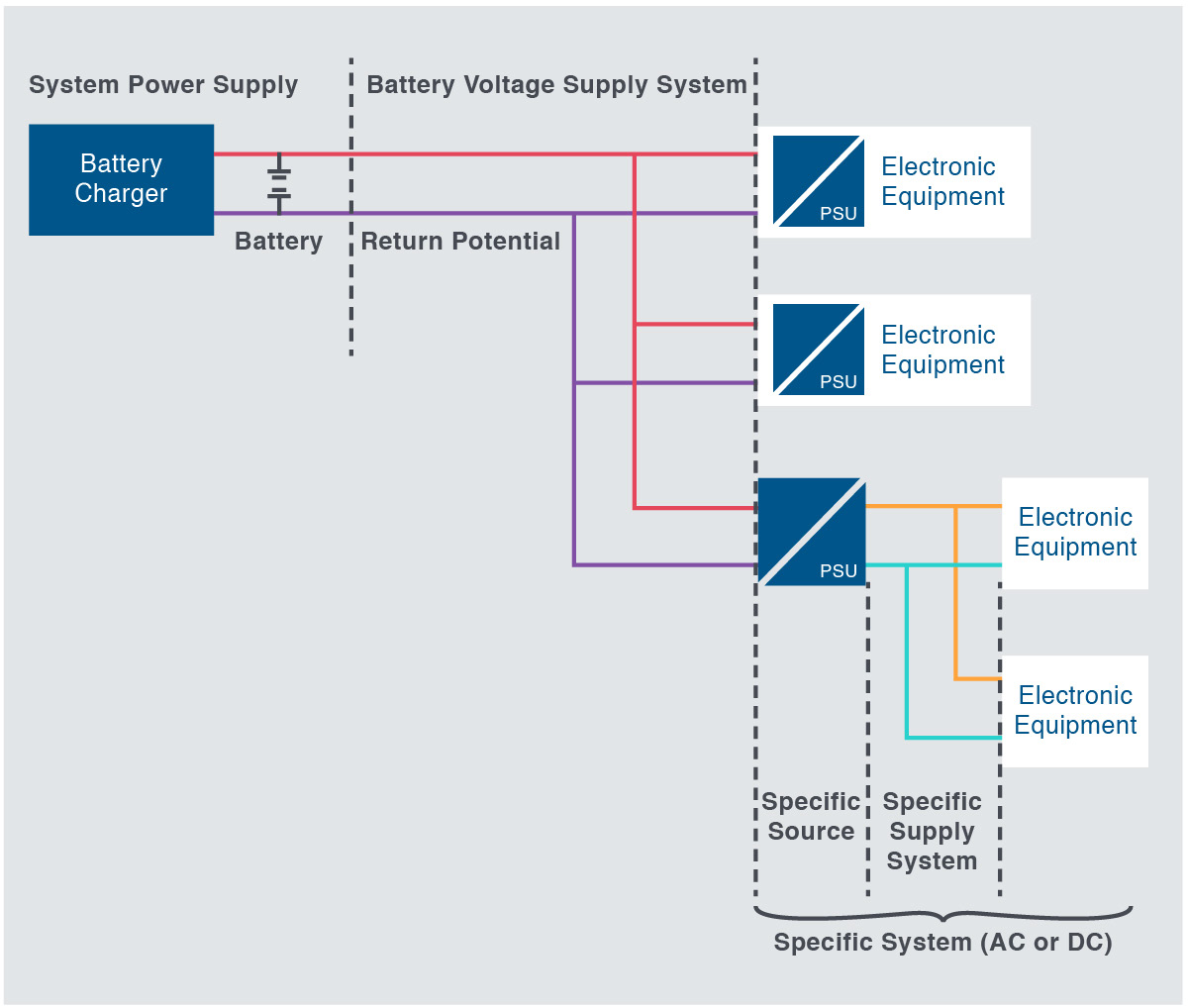

Figure 4. DC supply system example.

The standard defines a set of nominal battery voltages that can be selected: 24, 28, 36, 48, 72, 96 and 110V DC, but recommends the use of 24, 72, or 110 V. Limits for various transient and steady state conditions that power supplies must be able to withstand are based on the nominal battery voltage as shown in Table 3.

Table 3. Supply voltage limits included in EN 550155:2021.

| Supply voltage limits | ||

| Condition | Limit | Duration |

| Nominal Voltage | Vn | Continuous |

| Rated Voltage | Vn + 15% | Continuous |

| Continuous Voltage | Vn +25/- 30% | Continuous |

| Transient Voltage | Vn +/- 40% | 0.1 s |

| Extended Overvoltage | Vn + 40% | 1.0 s |

| DC Ripple Factor | 5% | Continuous |

EN 50155 also accounts for long and complete voltage interruptions. Equipment must be able to operate through supply change over with a 40% dip in supply voltage for up to 100 ms unless otherwise specified. Complete interruptions are divided into three classes designated S1 through S3, with S2 being the default test level, shown in table 4.

Table 4. Supply voltage interruption classes introduced in EN 50155:2021.

| Supply Voltage Interruption Classes | ||

| Class | Interruption Time | Performance |

| S1 | >0 ms | Resume normal operation after interruption |

| S2 | ≤ 10 ms | Maintain normal operation throughout interruption |

| >10 ms | Resume normal operation after interruption | |

| S3 | ≤ 20 ms | Maintain normal operation throughout interruption |

| >20 ms | Resume normal operation after interruption | |

2. ENVIRONMENTAL CONDITIONS:

There are six possible operating temperature classes, shown in table 1, with a default level of OT3. Any power supply solutions must also operate across a temperature range of -40°C to +85°C for at least 10 minutes during start-up, and temperatures must be managed in environments where there are extreme fluctuations. As of the 2017 edition, rapid temperature variations are taken into account. These variations can occur when trains enter and exit tunnels and applies primarily to equipment mounted outside the vehicle body.

3. SHOCK AND VIBRATION:

EN50155 references EN 61373:2010 for shock and vibration testing. That standard outlines allowable tolerance levels by breaking them into three categories.

Category 1: Equipment mounted directly on or under the body of the rail car.

Category 2: Bogie mounted equipment.

Category 3: Equipment mounted to the axel or wheels of the railway vehicle.

The category determines the severity of the testing that is required. Category 2, class B is the default requirement.

4. ELECTROMAGNETIC COMPLIANCE:

Electromagnetic compatibility (EMC) testing is usually mandatory and covered in EN 50121-3-2. EMC includes requirements for both emissions and immunity. The limits are based on the port type (battery source, auxiliary source, measurement or control, or communication). Power supplies are concerned primarily with battery and auxiliary power ports and have requirements outlined in table 5.

Table 5. Immunity limits

| Immunity Limits | ||

| Environmental Phenomena | Test Specification | Basic Standard |

| Fast Transients | ± 2 kV, 5/50 ns, 5 kHz | EN 61000-4-4 |

| Surges | 1.2 / 50 µs, 42 Ω, 0.5 µF, Line to ground: ± 2 kV Line to line: ± 1 kV | EN 61000-4-5 |

| RF Common Mode | 0.15 MHz to 80 MHz, 10 V (rms), 80% AM, 1 kHz | EN 61000-4-6 |

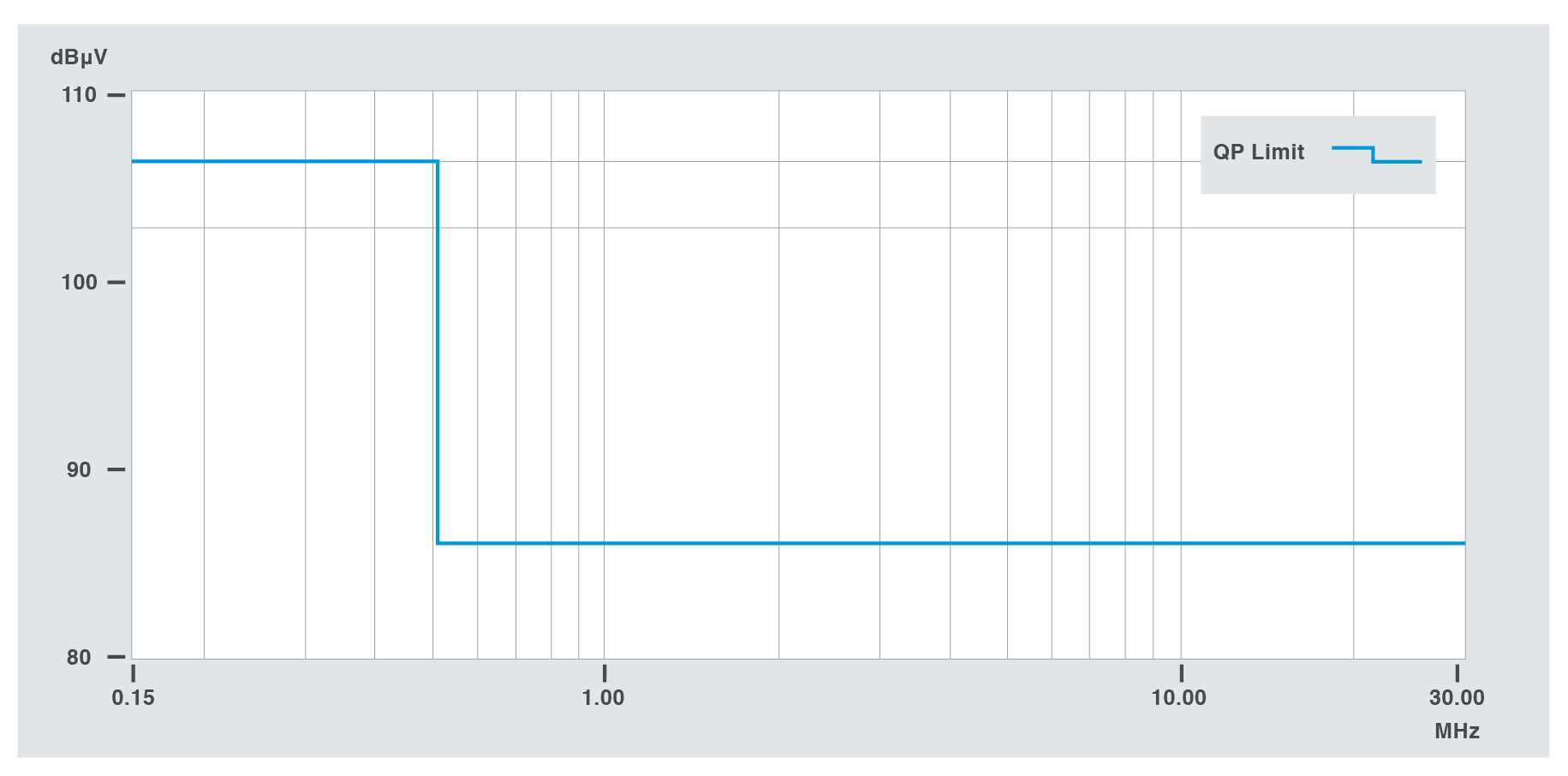

Figure 5. Conducted emissions limits.

5. PERFORMANCE AND RELIABILITY:

Railway applications always involve people, and performance and reliability are key enablers of both safety and quality. Power supplies, unless otherwise declared and documented according to the standard, must have a useful life of 20 years.

These five main areas of EN50155 reflect the real-world environment within which railway rolling stock must operate while accommodating for the utmost safety of people, whether it’s passengers, crew or anyone that comes close to where the train is traveling.

STANDARDS STEER BEL POWER SUPPLIES FOR RAILWAY APPLICATION

Power supplies are critical elements in rail system design and proper selection is fundamental to rail safety. That multiple standards apply simultaneously makes the selection more complex than it otherwise would be, so consulting an expert vendor is recommended, one with a long history of designing and developing power supplies in rolling stock for railway applications, as well as harsh environments.

Bel, through the Melcher brand, offers a wide breadth of AC-DC power supplies and DC-DC converters designed to meet the latest requirements of the EN 50155 standard. Melcher has a long history of designing and manufacturing rugged and reliable power supplies for railway applications and ensuring that products keep pace with the ever-changing safety requirements. The experts and engineers at Melcher can assist with finding the optimal EN 50155 compliant power supply solution for your railway applications.

Figure 5. Melcher power converter cassettes & subrack system.

Bel can create a custom versions of our many power supply designs to meet specific requirements by easily modifying standard designs to include features such as extended hold-up, long life, and inverse volt protection.

View our high-quality solutions for railway applications.

LEARN MORE