Some time ago, a panel at one of the fiber optics meetings discussed the topic “How to Finally Kill Copper in Data Centers.” The question is why kill copper? One can argue that since both fiber optics and copper cabling, and for that matter, wireless compete in the area of signal transmission, there should be winners and losers. However, a trip to your local supermarket should illustrate the fallacy of such an argument- if the meat and potatoes compete for a space on your dinner table, one of them should have disappeared from the supermarket shelves.

DOES COPPER HAVE A FUTURE IN DATA CENTERS?

In many a discussion on the cabling infrastructure, valid technical and economic facts have been replaced by myths, and common sense by emotional outbursts. In this author’s memory, no copper meeting ever discussed “killing optical fiber.”

In every single case, the benefits of each type of cabling need to be examined using technical information and common sense. The decision must be suitable for a specific application. The networks of the 21st century contain now, and will contain in the future, a multitude of means of connecting billions of users to the Internet. The fiber optics and copper cabling shall find their proper places. This paper examines the benefits of copper cabling in comparison to the optical fiber and discusses the new copper technologies for high-speed communications.

COPPER VS. FIBER MYTH

A popular myth goes, “the fiber optics is faster than the copper because photons are faster than electrons.” The optical fiber can deliver greater bandwidth, it is true, but the bandwidth is a different characteristic from the speed. The technical term describing the signal speed is the velocity of propagation.

The velocity of propagation of electromagnetic signal through a twisted pair copper cabling is about 0.66 of the speed of light in vacuum (C), the coaxial cable allows over 0.8C. The best single mode glass fiber transmits photonic signals at about 0.71C. Two messages sent from San Francisco- one over an optical fiber network and another by electromagnetic pulse over copper cabling- will arrive to New York at approximately the same time.

COST INCENTIVE OF COPPER

The panel mentioned above, could not find a sure way to kill the copper because the cost of a copper link is less than that of fiber optics. The cost of adding transceivers at both ends of the channels is the penalty to pay for other advantages of optical fiber. The competitive cost of copper connections within data centers (assuming 10GBASE-T switches and the category 6a cabling is about $0.50/gigabits per second (Gbps) per link. An installation cost equation includes the cost of connectors and cables proper. The copper and fiber cables are approximately at par with the possible lower cost of fiber. The copper connectors are less expensive, in particular, taking into account that a duplex fiber channel needs four connectors versus two needed for a copper link.

Copper is even less costly, however, if one considers the lifetime maintenance and repair. In one case, the replacement of a failed copper connector (an RJ45 plug) takes 2 minutes and less than $3. A repair of a failed FO link could require the replacement of a link at cost from $50 to $250. An optical transceiver could add about 20% to the cost of a laptop computer. If you have not seen many laptops with a fiber data port lately, the cost is the reason.

In the fiber optics transmission, the great source of power consumption is the dual transformation of the power from the electronic to photonic signal. Per The RP Photonics Encyclopedia (formerly the Encyclopedia of Laser Physics and Technology), such efficiency is typically about 50%. The dual transformation would quadruple the power consumption in comparison to the pure electronic transmission. The fiber cabling has lower attenuation as a function of frequency. The optical fiber is energy efficient when one needs to transport a huge block of data over long distances. However, a commonsense approach indicates that if both the optical receiver and transmitter are in the same building – and you have to pay for both the transceivers’ power consumption (and the building cooling) – you may want to have another look.

EXPLORING POE, IOT, AND EMI: UNVEILING CONNECTIVITY ADVANCEMENTS

A huge advantage of copper connectivity is the ability to support Power-over-Ethernet (PoE) where the same cabling can conduct the power as well as signals. The majority of the network switches on the market have built-in PoE options. The PoE also helps to dispel another myth that the copper is being replaced by wireless. In fact, each wireless transmitter, commonly referred to as a WAP (Wireless Access Point), is connected to a copper cable. Considering the places where WAPs are installed (ceilings, attics, rafters, towers, etc.), it is often difficult and expensive to route both a power cabling and network cabling to such places. Many WAPs have the same cable supplying the power and signals. The copper cabling PoE provides the most economical solution.

What's Next for Power-over-Ethernet?

Read the Application NoteA number of processes within the industrial and automated sensors generate an electrical signal. The Ethernet protocol dominates LAN; and the copper-based Ethernet over twisted wiring dominates the premise wiring market. The Industry 4.0 is envisioned as an integral part of the Internet of Things. Industry 4.0 grows from the present industrial automation by creating integral network to the office automation. The PC on an engineer’s desk becomes a piece of equipment used in the production process. That process is naturally accommodated by the copper-based Ethernet protocol.

The fiber has wider bandwidth, the longer reach and the optical cable is not susceptible to electromagnetic interference (EMI). Fiber optics transceivers are not immune to the EMI, by the way.

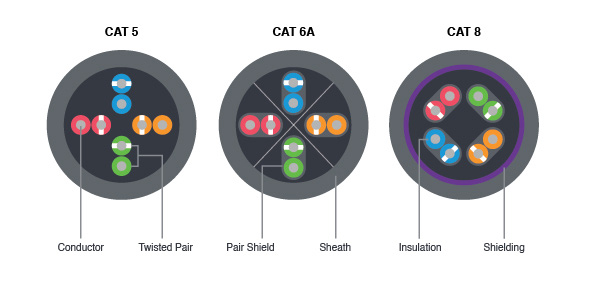

Figure 1. Construction of various standard cable types

The latest penetrations of copper cabling categories 7a, and 8 use shielded cabling. Many installations even of earlier cable generations 6 and 6a used the shielded cabling. The preferred cable construction is PiMF (Pair in Metal Foil). According to the current marketing surveys of new installations in Europe (Germany, Switzerland, Austria, France), PiMF cable is becoming the norm - approaching 90% of all newly installed copper cabling.

The fiber reach advantage, if examined in detail, may not be so important in some applications. Consider cases where the cabling is in the confines of a given network such as a data center or an office building. When the distance from your equipment to the next piece of equipment is about 20 to 40 meters, the ability to transmit a signal over a single mode fiber at a 500-meter distance becomes moot and will be a waste of resources to use the fiber in the application.

NEW STANDARDS FOR COPPER

The networking industry recognizes the tremendous potential of copper connectivity and continues working on development of new standards for high-speed copper interconnect. The ubiquitous and rapidly growing Ethernet is a main driver.

The IEEE 802.3bq standard published by the Institute of Electrical and Electronic Engineers, specifies the networking protocols for 25 and 40 Gbps Ethernet. The standard is a response to the industry demand for higher data density traffic in data centers.

Table 1. Major recent standard for high speed copper interconnect.

| No | Major Recent Standards | Brief Description |

| 1 | IEEE 802.3bq | 25 and 40 Gigabit/s Ethernet Protocol |

| 2 | IEEE 802.3bt | Power-over-Ethernet up to 100 W |

| 3 | IEC/ISO 11801-99 (in dev) | Class II, copper connectivity up to 2000 MHz |

| 4 | IEC 61076-3-110 | 3000 MHz copper connectors ARJ45 for Premise Wiring |

| 5 | IEC 60603-7-81 | Category 8.1 connectors |

| 6 | IEC 60603-7-82 | Category 8.2 connectivity |

| 7 | ANSI/TIA-568-C.2-1 | Category 8 Twisted pair cabling up to 2000 MHz |

IEEE 802.3bt expands the PoE by using all four wire pairs for transmission of power; it introduces Type 3 (60W) and Type 4 (100W) power sourcing equipment.

An international standard ISO/IEC 11801-99 (currently in the final stages of development) introduces the Class II copper cabling up to 2000 MHz It covers Category 8 and allows the use of alternative connectors, in addition to the RJ45.

IEC 61076-3-110 standard covers ARJ45 - Augmented RJ45. This is the first standard that expands the copper Premises Wiring connectors to 3000 MHz.

Image 1. Cat 8 ARJ45 patch cord

CATEGORY 8 STANDARD

In comparison to Category 6a, Category 8 increases the bandwidth of copper connectivity by a factor of 4, from 500 MHz to 2000 MHz. The Category 8 standard specifies improved channel return loss performance. It is useful to note that there are two Category 8s: Category 8.1 and Category 8.2. In practice, both use the same copper cables. Category 8.2 allows other connector types, in addition to RJ45.

Table 2. Selected parameters. Comparison of category 8.1 And 6a channels.

| Parameter | Category 6a | Category 8 |

| Max. Frequency | 500 MHz | 2000 MHz |

| Cable shielding | Shielded and Unshielded | Shielded |

| Channel length, m | 100 m | 30 m |

| No of connectors | 4 | 2 |

| NEXT at 500 MHz, dB | 26.1 | 27.9 |

| Return Loss at 100 MHz, dB | 12.0 | 16.0 |

| Return Loss at 500 MHz, dB | 6.0 | 10.7 |

Data centers, where high density of interconnect results in a large number of short transmission lines, are a natural environment for Category 8 applications. In this environment, the ease of maintenance and repair, short distances between transmitter and receiver, in combination with a wider bandwidth of Category 8 make copper cabling very attractive.

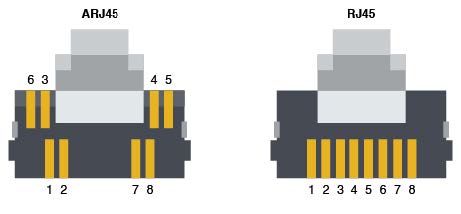

RJ45 AND ARJ45

Two copper connectors used for Category 8 twisted pair channels are RJ45 and ARJ45 (Augmented ARJ45). The RJ45 connector is one of the most popular connectors in the world. Network appliances, computer and data terminals have billions of RJ45 ports. The ARJ45 is a relatively new connector. Augmented RJ45 was derived from RJ45. Presently, at 3000 MHz, it is the fastest standard connector for twisted pair cabling. ARJ45 is also used with twinaxial cables. RJ45 and ARJ45 are very robust, inexpensive to make, and user-friendly connectors.

Figure 2. Comparison of a standard RJ45 to Bel's AJR45

TO AVOID MISCONNECTIONS: AN ARJ45 PLUG CANNOT BE INSERTED INTO AN RJ45

The RJ45 and ARJ45 use different approaches to control differential Near End crosstalk. The RJ45 uses compensation to reduce the differential NEXT. Compensation is a method of creating the crosstalk equal in amplitude but opposite in phase by adding capacitive and inductive elements. ARJ45 uses isolation to avoid differential NEXT. A Faraday cage is built around each differential pair. As a result, ARJ45 is better suited for high frequency applications.

Table 3. ARJ45 and RJ45

| Properties | RJ45 | ARJ45 |

| Contacts | 8 | 8 |

| Support Auto-negotiation | YES | YES |

| Support PoE | YES | YES |

| Durability Cycles Type 1 | 750 | 750 |

| NEXT at 500 MHz, dB | 26.1 | 27.9 |

| Return Loss at 100 MHz, dB | 12.0 | 16.0 |

| Return Loss at 500 MHz, dB | 6.0 | 10.7 |

SUPPORTING 25 AND 40 GBPS ETHERNET

Customers demand the connectivity that can be plugged into the existing 1, 2.5, 5.0 and 10 Gbps equipment and will support 25 and 40 Gbps switches and peripherals. Such connectivity shall deliver the robust transmission performance and support the all-important auto-negotiation. The Category 8 copper cabling is such connectivity.

The best way to connect the RJ45 ports and take advantage of ARJ45 performance is to combine RJ45 and ARJ45. That is commonly done by utilizing a patch cord with ARJ45 plug on one end and RJ45 plug on another end. The IEC standard design provides means to prevent plugging ARJ45 into RJ45.

Figure 3. Category 8.1 Data Center Channel RJ45-ARJ45-RJ45 can connect all the existing RJ45 ports and support applications from 1 GbE to 40GbE.

The Category 8.1 channel can combine the advantages of both the common RJ45 and the high performance ARJ45 and deliver robust performance. The RJ45 plugs at the channel ends allows all to utilize all the existing equipment. The RJ45/ARJ45 channels fully support the auto-negotiation.

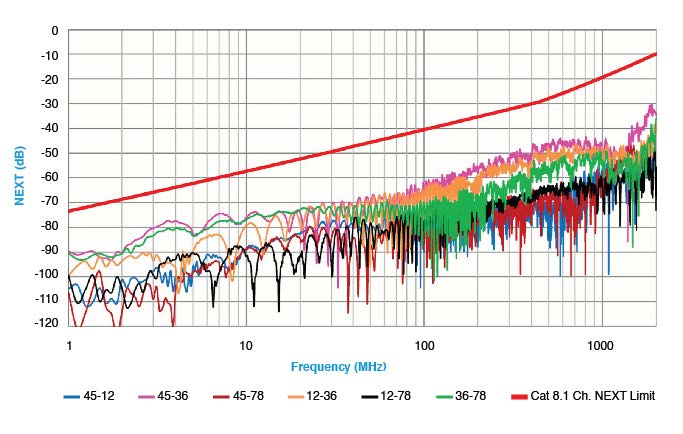

Figure 4. Category 8.1 Data Center Channel NEXT test data.

Make no mistake, copper cabling will continue to compete with and complement fiber optic cabling. Both optical fiber and copper cabling networks will continue to coexist. The rumors of copper cabling death are somewhat premature. Copper cabling is not dead and is not going to die anytime soon. Category 8 and ARJ45 will extend the life of copper connectivity for many years to come.

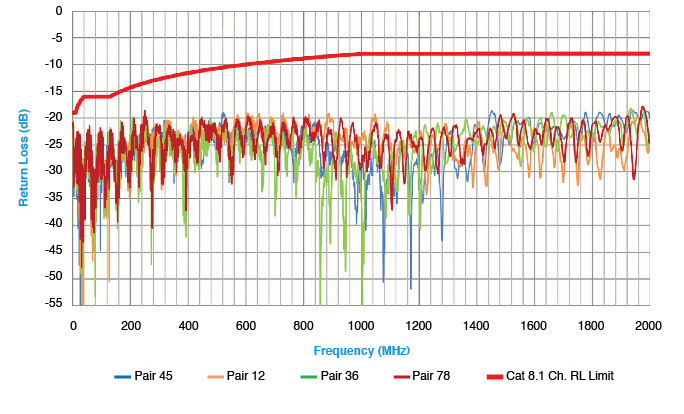

Figure 5. Category 8.1 Data Center Channel Return Loss test data.

View Bel’s Cat 8 ARJ45 Cable Jack

EXPLORE PRODUCTS