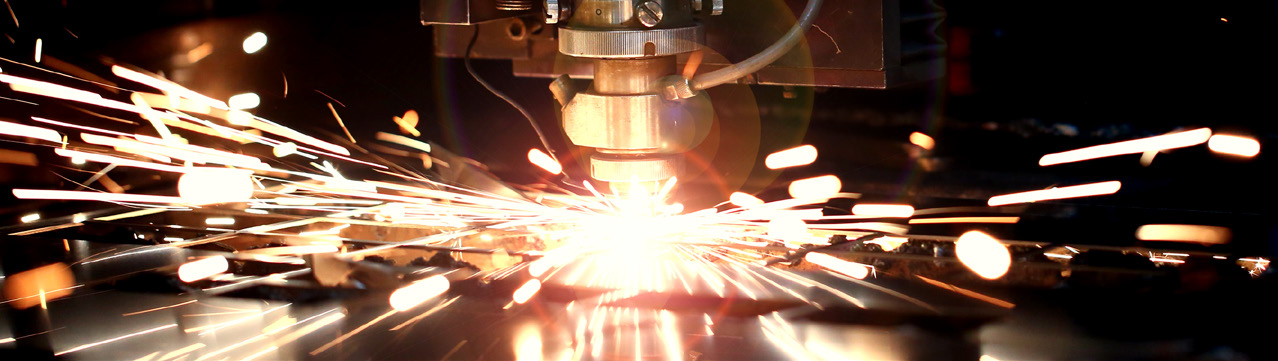

There are many growing and emerging applications that are pushing the boundaries of precision, power and performance for power supplies. For instance, applications such as laser cutting, plasma cutting, welding, printing and other fabrication technologies are demanding more capable AC-DC converter power supply units (PSUs). Considering the growth in the laser cutting market, as well as the extremely competitive landscape, there is substantial room for PSU improvement to enhance laser cutting performance.

Many commercially available PSUs aren’t up to the task of providing reliable power to tens of kilowatts with the necessary precision and features, such as supporting high frequency pulsed loads. Part of addressing these challenges is knowing what performance requirements and features are needed from a PSU for these demanding applications. This application note is geared toward educating professionals designing or installing high-performance and precision equipment with versatile PSU requisites about modern PSU technology and how to select an appropriate PSU solution.

Challenges of Selecting a PSU for High-Performance Applications

Applications, such as laser cutting, are pushing the boundaries of PSU performance. The latest laser cutters use high frequency pulsed power to cut a wider variety of materials, faster, with greater precision, and often without the need for post process machining or specialty cutting tools. This is part of a general trend of laser cutting machines becoming more sophisticated and automated to better compete with traditional machining technologies. Hence, laser cutting machines have been increasingly used in automotive, shipbuilding and aviation manufacturing.

One of the hurdles to overcome for modern laser cutting machines is a limitation in reliability and performance stemming from the quality and performance of the laser cutting machine’s PSU. This is a result that many of the PSUs available on the market that end up in laser cutting machines are general purpose 3-phase AC-DC converters. Also, to reduce machine costs, some designs and laser cutting machine assemblers prefer to use the lowest cost PSU that meets the minimum requirements of the laser. This, however, often results in sub-optimal performance, frequency maintenance and replacement of the PSU resulting in excessive downtime, slower laser cutting speeds and reliability issues that ultimately reduce the precision and penetration of the laser cutter.

The main areas of consideration when selecting a PSU for modern laser cutters is the ability to handle high frequency dynamic loads, wide AC input voltage, variable DC output voltage, monitoring and reliability even under extreme operating conditions common to industrial environments. The following section discusses these considerations.

Handling High Frequency Dynamic Loads

The success of the latest laser cutters and laser cutting applications relies on the quick and efficient cutting of a diverse range of materials with the utmost accuracy. This requires extremely precise control of the laser peak power, pulse frequency and duty cycle. Many PSUs commonly used for laser cutting applications are not designed to provide accurate power output and reliability for high frequency dynamic loads. Not only is an underspecified PSU more likely to fail under these operating conditions, but the failure could allow for surging and interference that could damage other electronic components of the laser. It is increasingly important to leverage a PSU with the appropriate circuitry to reduce oscillations at the load and optimize the power factor between the PSU and load.

Accommodating Wide AC Input Voltage Ranges

It is not uncommon for a laser to be designed in one country, including many parts built in other countries, assembled in a different country and shipped anywhere in the globe. Capability with global grid voltage, including domestic and industrial voltages, is a competitive advantage for laser system designers and suppliers. Hence, a laser cutter PSU capable of a wide range of AC input voltages can reduce the complexity of having to design, supply or service laser cutting product families with PSUs fit for each grid supply voltage range. This not only saves design time during development, but also simplifies future maintenance and servicing of laser cutting units with higher volumes of common parts.

Enabling Variable DC Output Voltage Setting & Monitoring

Many types of lasers are incredibly sensitive to variations in voltage, for which even small voltage changes can result in large voltage or current swings experienced by the laser. In order to ensure reliable and safe laser operation, laser cutter PSUs need to have precise DC voltage control and monitoring systems. As laser cutters are often used for a variety of different applications and material thicknesses, wide variability of PSU voltage output is also helpful to ensure precise laser cutter operation. As the DC output of a laser cutter PSU depends on the behavior of the 3-phase AC input, careful monitoring of the input voltage to the PSU is also essential for an accurate DC output voltage. This requires real-time monitoring of the input and output electrical parameters and a sophisticated PSU controller capable of environmental and operational variations common to industrial facilities.

Reliability in Extreme Environments

Early laser cutting systems were previously only found in pristine laboratories or their own dedicated areas of a manufacturing facility. With laser cutters now entering the same space as other cutting machines, they must also now deal with the same debris and fluctuating environmental conditions of extreme industrial environments. In these conditions the ingress of particles, corrosive/reactive gasses, cutting debris and moisture can dramatically reduce the lifespan of electrical components or otherwise degrade their performance over time and in unpredictable ways.

Given the need that laser cutters have for precise input power, a reliable and rugged PSU is becoming increasingly important. For some environments, fan-cooled PSUs are simply too susceptible to damage from environmental ingress, and more reliable calling methods are required. One such technology, using cold plates and precision designed thermal management of internal components and structures, can ensure long-term reliability in even the harshest industrial environments.

The Power of Leveraging Innovative PSU Technology

Addressing these considerations for an industrial-grade PSU with optional capability to support high frequency dynamic loads to 100 kHz is the Bel Power Solutions TCP3500/4000 and TXP3500/4000 Series 3-phase AC-DC converters. The TCP/TXP Series of converters is designed with a universal 3-phase AC input voltage range of 115-277 V and 200-400 V (line to line), providing world-wide compatibility with industrial and public grid power systems. This capability meets the need for laser cutting and other industrial machines to operate in facilities around the globe.

Explore Bel's Enclosed High Power Solutions

View ProductsThese converters are modular, with the ability to be combined in parallel operation up to 16 units, reaching 57.6 kW of total power bolstered by active current sharing to avoid excessive loading on any single unit within the array. Though the individual power output of a signal unit can reach 4000 W, these converters are compact enough for 4 units to fit within a 2u 19" rack. Such a small footprint and high output power fulfills both the need for compact and high power density (16 W/in3) PSU solutions and high overall output power.

Moreover, the TCP/TXP converter family includes models with nominal output voltages from 28 V, 48 V and 90 V with upcoming 60 V options, with adjustable ranges of 10 to 32 VDC, 10 to 50 VDC and 30 to 100 VDC. These adjustable voltage ranges accommodate many of the numerous varieties of laser cutting and industrial machine input voltage requirements. A key advantage of the TCP/TXP Series PSUs is the ability to adjust the full range output voltage setting within 5 ms using an industry-standard RS485 interface, with an extremely fast 200 microsecond response to the Vout set command. Additionally, each TCP/TXP PSU unit comes equipped with an internal voltage monitoring system based on a dsp architecture, which helps to ensure that voltage is optimal at each of the 3-phase AC inputs and the desired DC output is delivered regardless of the laser cutter or industrial machine.

Most importantly for laser cutting applications is the optional pulse load operation capability, which can accommodate DC to 100 kHz frequency dynamic loads with 0 to 100% duty cycles. This feature is possible due to the meticulous design of the path inductances and the addition of speciation capacitors that eliminate oscillations on the load. This feature means that the TCP/TXP family of PSUs can support even high frequency dynamic loads without fatigue and dratting due to internal component failures common to generally available PSUs on the marketplace.

Further enhancing the reliability of the TXP PSUs, the TCP family of PSUs is designed with a cold-plate cooling surface, which eliminates the need for internal fans. Liquid cooling or conduction cooling can be used to keep the TCP family PSUs at a good operating temperature while enabling reliable performance with MTBFs far beyond generally available PSUs. There are also TCP3500 version with integrated cold plate that also meet semiconductor industry requirements for Silicone-Free Gap Pads/Gap Fillers, as the cold plate feature eliminates air flow and special design mitigates potential process contamination.