Specifying Power Converters for Rolling Stock Application

Modern rail vehicles are packed with electronics for communications and control with passengers also increasingly expecting cellular repeaters and Wi-Fi services with ‘clean’ AC mains and USB DC power available at each seat. Because of the environment and the diverse nature of connected equipment, power conversion is becoming increasingly distributed. Each converter that interfaces between the raw DC bus, the train electronics and passengers’ expensive portable devices has to be designed to meet the electrical specification of the bus voltage and also the harsh physical environment of a rail application.

Rolling Stock Needs Specialized Equipment Power Supplies

Power in rail rolling stock was originally all about traction, lighting and rudimentary signalling with typically raw 110VDC from the onboard batteries connected to everything. Switchgear on the DC bus did not have surge and transient limiters on the basis that they would degrade with time and couldn’t be guaranteed to always function so individual equipment had to stand the full level of overvoltages, drop-outs and surges that resulted. It didn’t matter though that the lights occasionally brightened or dimmed.

Today it’s very different - modern rail vehicles are packed with electronics for communications and control with passengers also increasingly expecting cellular repeaters and Wi-Fi services with ‘clean’ AC mains and USB DC power available at each seat. Because of the environment and the diverse nature of connected equipment, power conversion is becoming increasingly distributed. Each converter that interfaces between the raw DC bus, the train electronics and passengers’ expensive portable devices has to be designed to meet the electrical specification of the bus voltage and also the harsh physical environment of a rail application.

Specifying the Challenge

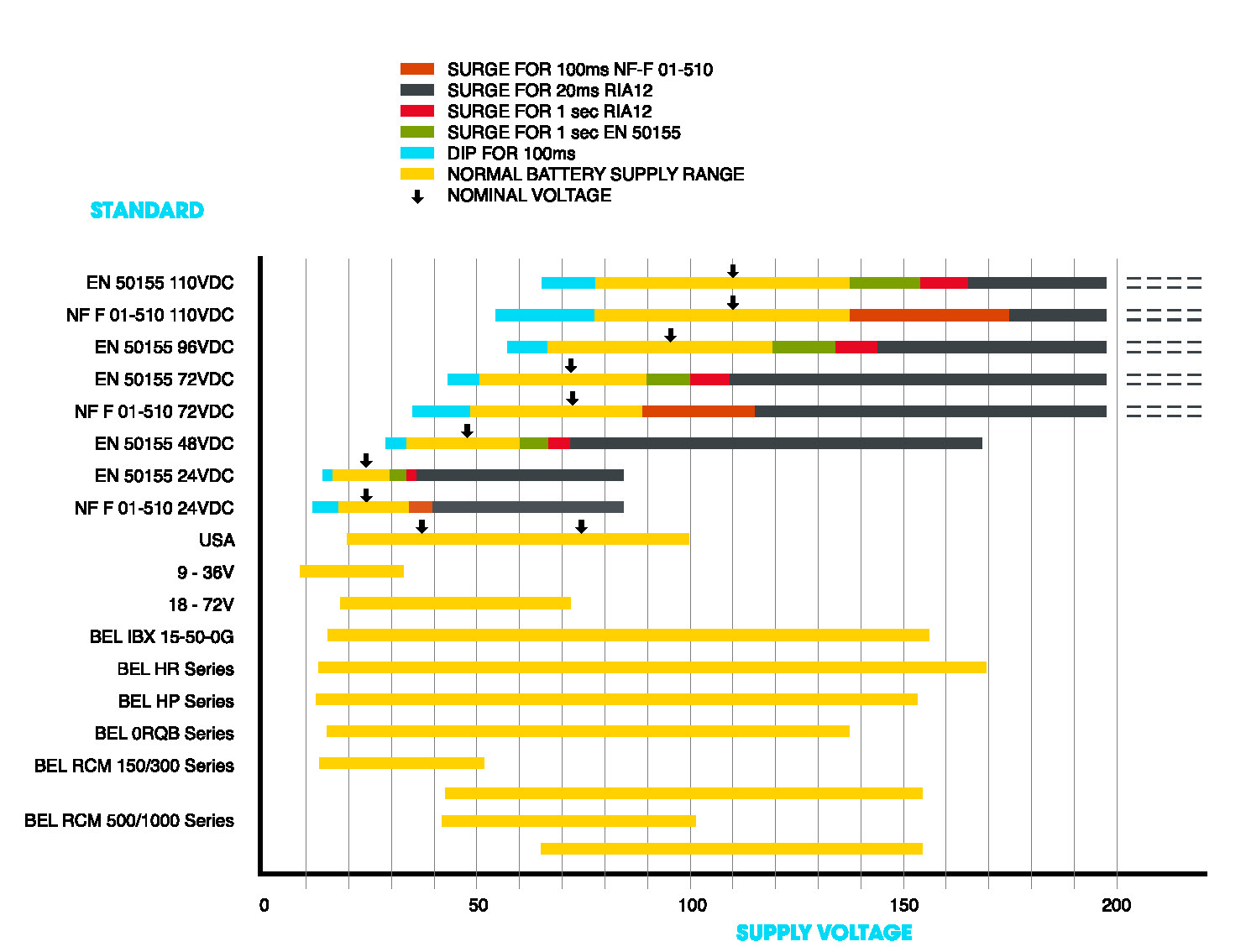

Recognized internationally, EN 50155 is the European standard for electrical equipment in rolling stock, covering functionality and performance under the particular rail environmental conditions. Electrical stresses are covered along with EMC, safety and mechanical conditions such as vibration, shock, bump, watertightness and much more. Of particular concern to power supply manufacturers is the input voltage specification which has several possible nominals with dips, drop-outs, surges and transients. Figure 1 summarizes the specification in EN 50155 with a comparison to other older rail standards, British RIA-12, French NFF 01-510 and the USA. High kV transients are not shown and are attenuated by TranzorbsTM or similar. The ‘wide’ input ranges of standard commercial DC-DC converters, 9 – 36V and 18 – 72V are given as a reference showing poor overlap to rail requirements. As examples, some commercial DC-DC converters from the Bel Power Solutions range designed specifically for rail are also shown covering all of the nominals.

Melcher™ Cassettes & Converters

Discover the PossibilitiesFortunately, for the relatively low power distributed converters in communication and control equipment, the high energy surges lasting for up to a second and high voltage spikes are usually handled by a pre-conditioning stage, leaving just the wide continuous operating voltage to contend with. For example, a 110 VDC, EN 50155 nominal input can range from 77 to 137.5 VDC. If compliance with the RIA-12 standard is required with surges of 3.5 x nominal for 20 ms, up to 385 VDC, an active pre-regulator or similar is normally needed as the energy is too high to simply absorb in transient limiter components.

EN 50155:2017 also includes a specification for total supply interruption for 10 ms in some applications, designated ‘Class S2’ and interruptions for 20 ms, ‘Class S3’.

Figure 1.The range of power supply input voltages

Another way that commercial power converters are unlikely to match the specifications is in compliance with environmental tests. EN 50155 references EN 61373 for shock, vibration and bump with requirements split into three categories: body (class A and B), bogie and axle-mounted, the last being most severe. Depending on the intended locations other specifications may apply such as immunity to water ingress and salt mist. EMC of course is an additional consideration with specifications applicable for ESD, Surge and transient immunity, also RF susceptibility along with conducted and radiated emissions according to EN 50121-3-2. Dry and damp heat specifications also apply and typical operating temperature ratings are -40 to +85°C but may be transient.

Suppliers of power converters must also prove compliance by extensive test records, build documentation and predictions and proof of reliability of both hardware and any embedded software. All this is along with any application-specific requirements such as ‘useful lifetime’ which could be 30 years.

Types of Power Converters Typically Used

DC-DC converters with various form factors are used in rolling stock depending on the power level and application. Chassis-mounted parts are typical at higher power with appropriate ruggedization to meet the shock and vibration requirements with any open PCBs lacquered. Up to around 600 W, the Eurocassette style is very popular. This is a rack-mounting product using the standard DIN 41612 H15 connector and is available at many power levels and with many options. Both chassis-mounted and cassette style products will typically have ‘bus’ outputs of 12, 24 or 48 V and will often have options to include extra filtering, reverse polarity protection and extended hold-up time. ‘Hold-up’ or ‘ride through’ can be quite challenging for low nominal input voltages. For example, to hold up a 100 W supply at 80% efficiency for 10 ms for ‘Class 2’ applications with an input range of 16-36 V around a 24 V nominal would need a capacitor on the input of about 8,000 µF rated at 40 V – about 2.5 cu-in or 40 cu-cm size. This is significant size and cost and a major contributor to the overall reliability and life time calculations. EN50155 describes interruptions as being caused by input short circuits, so a series input diode is also necessary to isolate the hold-up capacitor, which causes additional power loss and voltage drop requiring the input range of the converter to be extended. Other solutions for hold-up might be to internally boost the input to a higher voltage so a smaller capacitor can be used for the same energy storage but in any case, inrush current and charge rate into the capacitor has to be controlled and may limit the repetition rate of allowable drop-outs to 1 in 10 seconds or so.

Some products have the ability to connect converter outputs in parallel for extra power or redundancy with associated signalling. The input voltage range of the converters will often be wide to encompass as many nominal battery voltages as possible with their dips and surges.

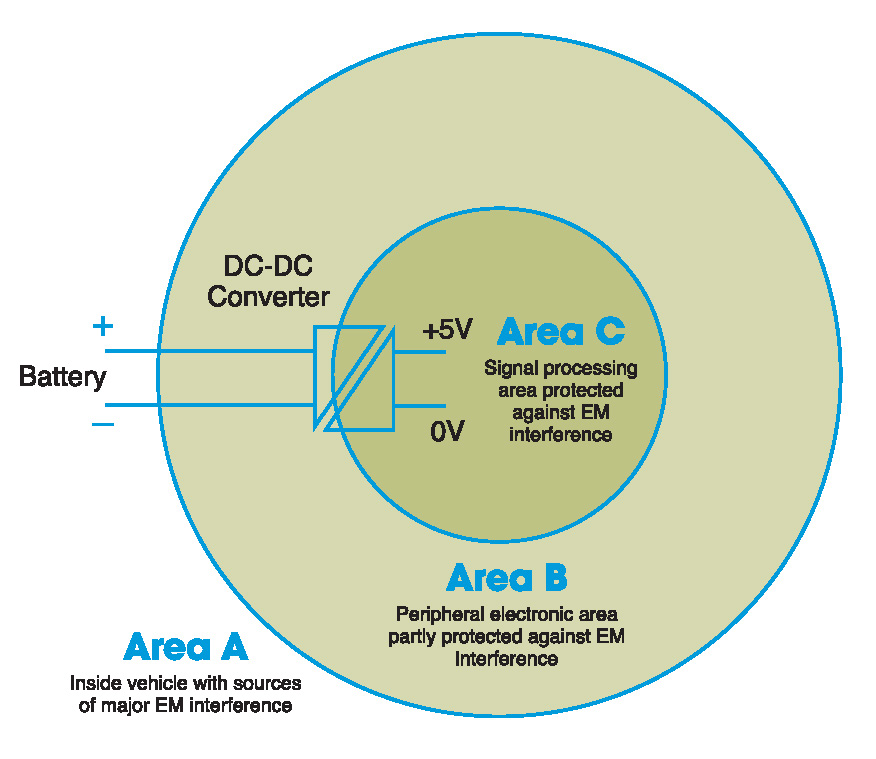

Figure 2.Rail system EMC areas, A, B, C

Note that accessible fuses are often not allowed in power supplies in rail applications so external fuses or contact breakers may be necessary.

Board mounted products are also used at up to around 100 W giving tightly regulated low voltage outputs for digital and analog circuitry. These may also be powered directly from the DC bus so often will need surge and transient as well as environmental protection.

Isolation is generally required of DC-DC converters with levels defined by the application but is typically BASIC or REINFORCED.

EN 50155 includes a diagram identifying system EMC area A, B and C shown in abbreviated form in Figure 2 with the typical positioning of a DC-DC converter.

Practical Solutions

With the Melcher branded products, Bel Power Solutions is a major supplier of DC-DC converters that comply with EN 50155. Isolated, chassis-mounted parts are available in the RCM series from 150 W to 300 W with input ranges of 14.4 – 50.4 VDC and 43.2 – 154 VDC covering nominals of 24 V, 28 V, 36 V, 72 V, 96 V and 110 VDC with brown-outs to 0.6 x Vnom and surges to 1.4 x Vnom. 500 W and 1000 W parts are available with inputs of 43.2 – 100.8 VDC for 72 VDC nominal and 66 – 154 VDC for the 110 VDC nominal input also covering 0.6 x Vnom brown-outs and 1.4 x Vnom surges.

Eurocassette DC-DC converters are a major feature in the Melcher range with isolated products rated from 50 W in the M series to 288 W in the HR series . A wide selection of input voltages is offered with minimums down to 8 VDC and maximums up to 385 VDC in the ‘K’ series (Figure 3). Non-isolated cassettes are available up to 576 W in the PSK/PSS series with input voltage rating down to 18 V, dependent on variant. Even board-mounted products are available in their PSA/PSR, PSB and IBX non-isolated series with wide input ranges that are suitable for rail applications.

Figure 3. The HR series (left) and RCM series (right) of DC-DCs from Bel Power Solutions

All the products from Bel Power Solutions for rail applications are ruggedized and come with a variety of options to make assembly and certification of a complete system solution easy. Parts in the RCM series for example are available with optional 10 ms hold-up and ‘OR-ing’ diodes for redundant applications.

Designing for compliance with EN 50155 is not an easy task in electrical and environmental conditions that are just about as hostile as it gets. Commercial ‘off the shelf’ solutions will most often simply not fit the specification, especially for long term reliability. Specially designed converters from a company such as Bel Power Solutions are a safe solution with a long track record.

Explore Bel's Variety of Railway Solutions

Under the MELCHER brand, Bel provides the leading manufacturers in the railway and transportation industry worldwide with high performance, rugged DC-DC and AC-DC converters. With almost 50 years of design and manufacturing experience MELCHER products are designed to meet the highest national and international standards for harsh environments, safety and EMC/EMI and undergo rigorous and extensive EVT/DVT and HALT/HASS test.