Demand for faster and more reliable connectivity is greater than ever, and fiber optic technology is critical in meeting this demand. While optical networking is generally more expensive than traditional copper-based solutions, its unique characteristics make it the ideal choice in many applications. This article explores the key advantages that fiber networks have over copper and the different types of transceivers that exist to convert between optical and electronic signals. By understanding the benefits of fiber optics over copper and the important role that transceivers play, companies can make informed decisions to ensure the best possible performance of their communication networks.

FIBER HAS A HIGHER BANDWIDTH AND IS RELIABLE OVER LONGER DISTANCES

Nothing travels faster than a photon, and optical signals can transmit data faster, and over longer distances, than electronic signals can be transmitted unaided over copper. To achieve modern 10 Gbps speeds, the cat 5 cabling common in many existing installations must be upgraded to cat 6 or cat 6a cable. However, even with cat 6a, the maximum distance at which 10 Gbps speeds can be reliably achieved is 100 meters. The speed of fiber, on the other hand, is currently only limited by the speed of the optical transceivers, with a theoretical limit in the tens of terabits range and may be reliably transmitted over several kilometers. When speed and distance are the most important criteria, optical technology is the only choice.

Table 1. Comparison of copper and fiber data rates and transmission distances

| Cable Type | Standard | Rated Speed | Max Distance |

| Cat 5 | 1000BASE-TX | 1 Gbps | 100 m |

| Cat 5e | 2.5GBASE-T | 2.5 Gbps | 100 m |

| Cat 6 | 5GBASE-T | 5 Gbps | 100 m |

| Cat 6a | 10GBASE-T | 10 Gbps | 100 m |

| Cat 8 | 40GBASE-T | 40 Gbps | 30 m |

| OM4 Fiber | 100GBASE-SR4 | 100 Gbps | 125 m |

| OS2 Fiber | 100GBASE-ER4 | 100 Gbps | 2000 m |

| OS2 Fiber | 100GBASE-FR1 | 100 Gbps | 40,000 m |

Notable applications are military communication networks, which must send large amounts of data quickly and reliably over large distances. Electronic warfare systems, for example, combine an array of components, including antennas, sensors, and processing equipment, all of which work together to gather and communicate intelligence information. These components may be situated at great distances from each other and must be able to reliably communicate to maintain situational awareness.

FIBER HAS LOW SPACE, WEIGHT, AND POWER (SWaP)

When weight is a key consideration, such as in aircraft and satellites, optical also wins. Optical fiber weighs significantly less than copper wiring, roughly four pounds per 1,000 feet, while the same length of copper weighs nearly 10 times as much. More weight in applications such as these can mean reduced payload capacity, limited range, and decreased fuel efficiency.

Where weight is important, physical space often is too, and fiber has a clear advantage there as well. Cat 5e cable takes over 100 times more space than a comparable amount of fiber optic ribbon.

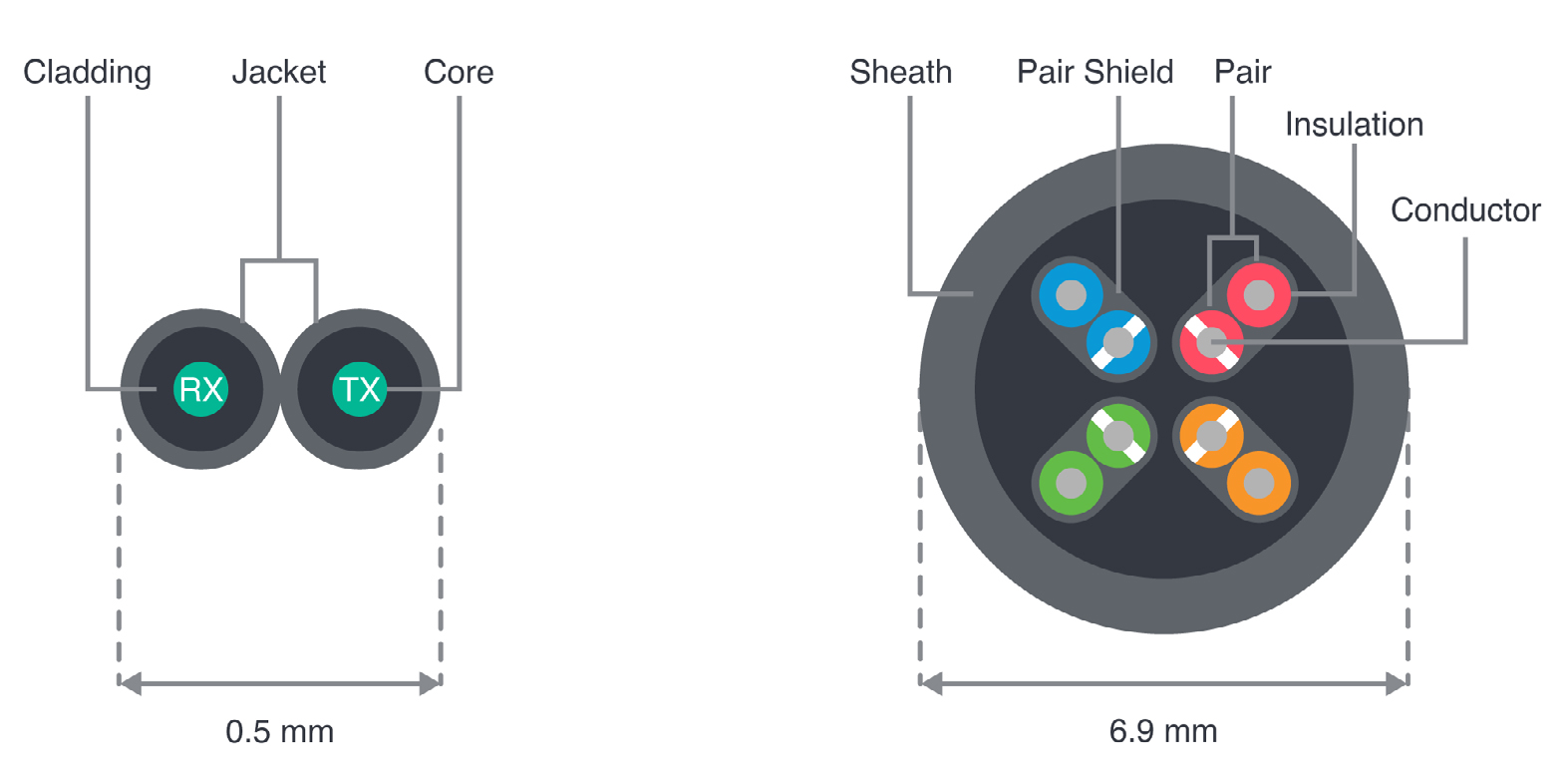

Figure 1. Comparison of a typical fiber cable (left) to Cat 5 copper cable (right)*.

* Not to scale

Optoelectronic technology is consequently common in military aviation, where some applications have little choice in the matter; the amount of optical fiber in fighter jets is said to measure in miles, making copper an impractical solution. Beyond the military, optical is now being increasingly adopted in the commercial aviation sector as the benefits of space and weight reduction outweigh the cost of implementation.

Reduce SWaP With Fiber

Learn HowFIBER IS IMMUNE TO ELECTROMAGNETIC INTERFERENCE

Another characteristic that distinguishes optical technology from electronics is that optical networks are immune to electromagnetic interference (EMI), which makes them impossible to jam or render inoperable using indirect means. Optical signals are also exceedingly difficult to intercept unnoticed. Optical systems are therefore considered both more robust and more secure than traditional electronics. These qualities are extremely attractive in the military market beyond just fighter jets.

The common thread among the applications where optical technology is being widely adopted is that they are all demanding -- they are applications in which performance should not be compromised. Converting from one domain to another must be accurate and reliable. Connectors should be reliable and durable especially so in ruggedized military and industrial applications.

OPTICAL AND ELECTRICAL CONVERSION REQUIRED

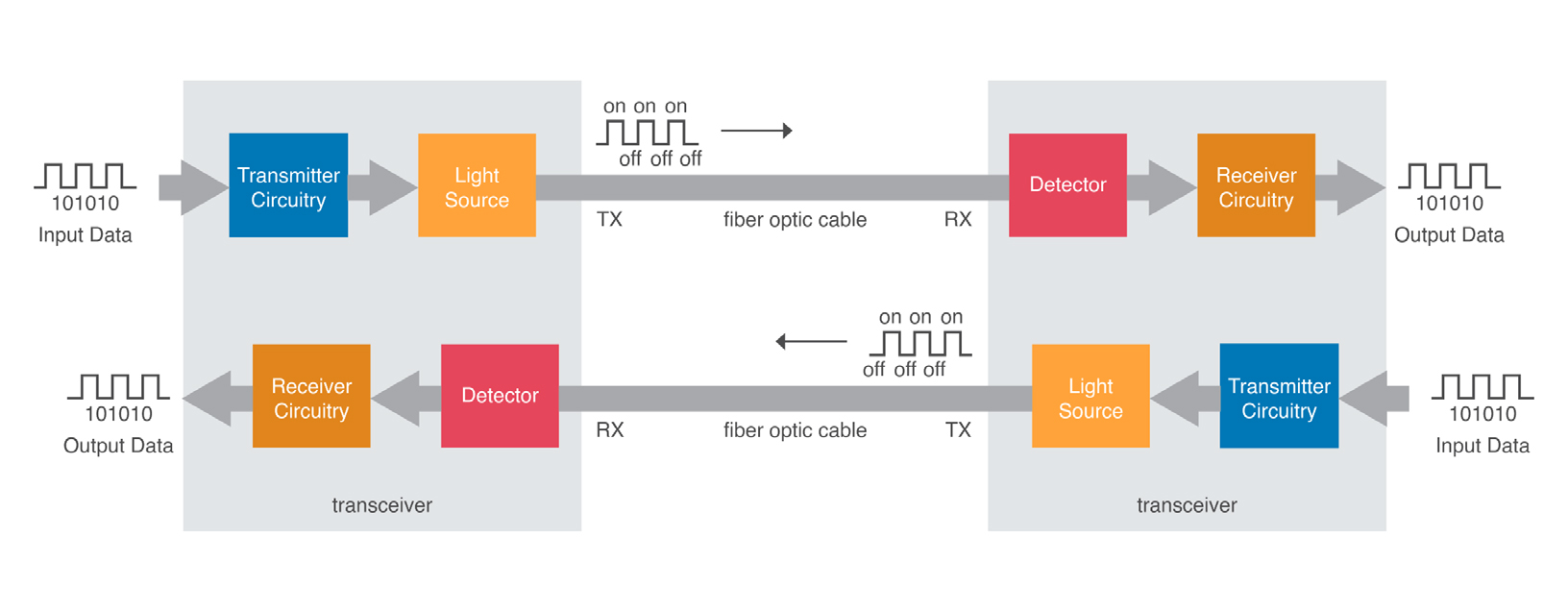

For electronic devices to take advantage of the benefits that fiber offers, the optical signal must be converted to and from the electrical domain. This is done using optical transceivers.

Figure 2. Simplified block diagram of two optical transceivers sending and receiving data.

To transmit, the electrical signals are used to drive a light source, which emits light at one or more of the specific wavelengths used in fiber networks. The three most common wavelengths used are 850 nanometers, 1310nm, and 1550nm, though there are others. The emitted light is channeled into an optical fiber inserted in the transceiver module.

On the receiving end, incoming light is directed into a PIN photodiode, which absorbs photons and emits electrons in response. Internal electronics condition and route the signal according to the specific physical and electrical protocol that the transceiver is designed to interface with, such as those defined by IEEE 802.3.

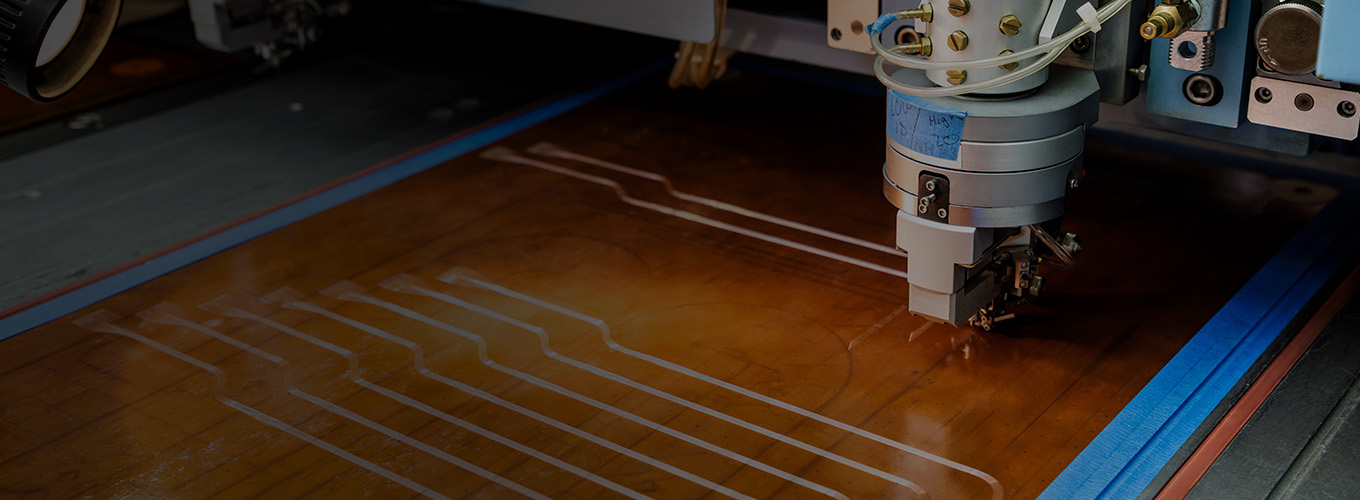

Custom Routed Flexible Fiber Circuits

Optical Fiber SolutionsSTANDARD AND PROPRIETARY TRANSCEIVERS

A range of transceiver solutions exist, including both standardized and proprietary designs. In the telecommunications industry, the so-called Multi Source Agreement (MSA) defines several standardized optical transceivers to enable cross-vendor compatibility. The MSA includes common transceiver form factors, such as the Small Form Factor (SFF) and the Small Form Factor Pluggable (SFP).

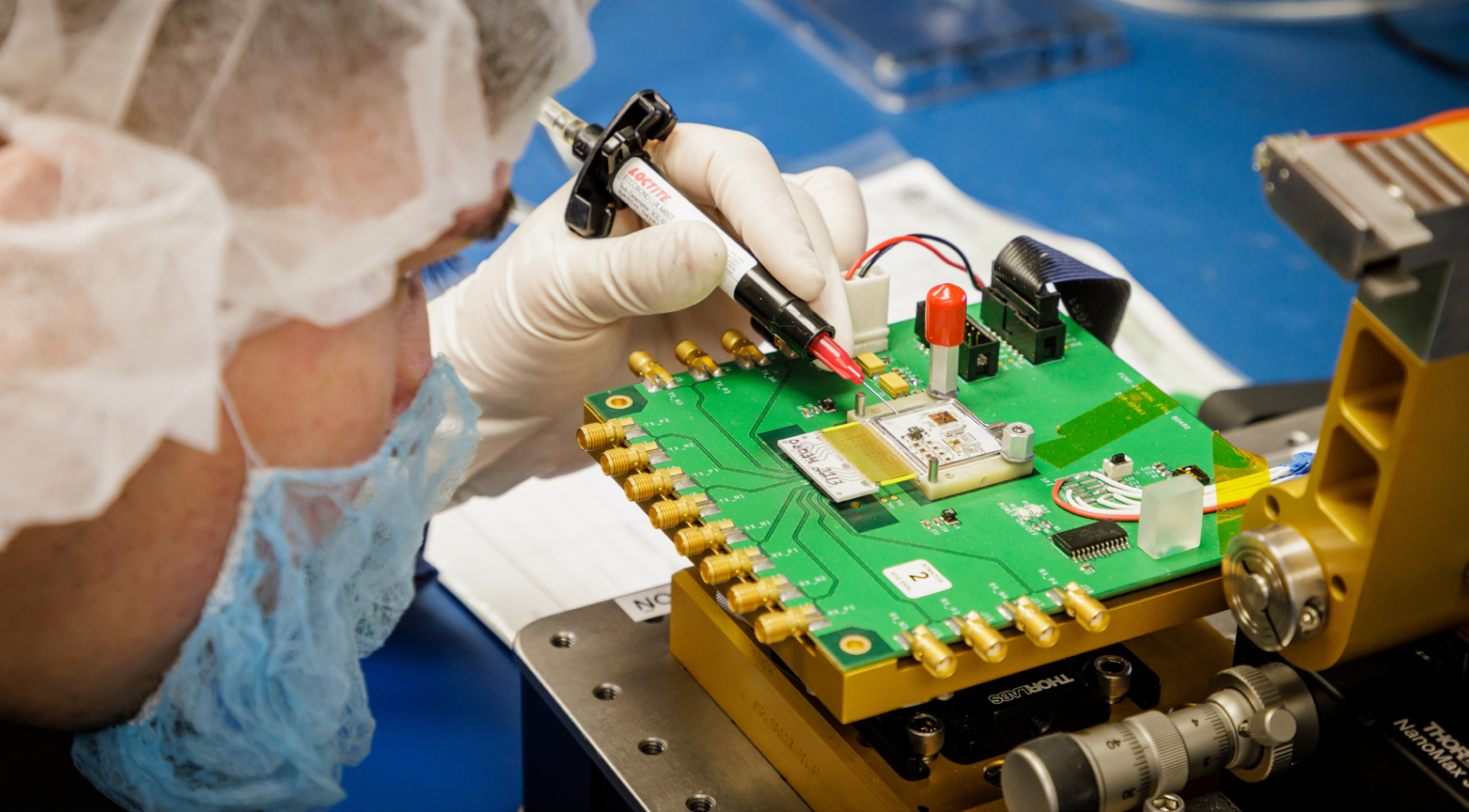

For more unique or advanced applications, such as defense and aerospace, a standardized solution often doesn’t cut it. In these cases, the performance, size, and security of the transceiver is critical. Cinch performs its own design, manufacturing, and test, assuring quality. With long experience, Cinch has the expertise to engineer and build rugged custom optical transceivers that are not only highly reliable, but also often smaller than competing products, and consequently draw less power.

Figure 3. Cinch transceiver being assembled on test board.

FIBER’S IMPORTANCE WILL CONTINUE TO GROW

The explosive growth rate of data being communicated between a multitude of devices all around the globe is not expected to tail off any time in the foreseeable future. Although copper offers some benefits in the short term, such as lower cost, the performance and low SWaP of fiber continues to propel its growth. Meanwhile, the drive to make commercial and military equipment lighter and more efficient will only increase in importance.

These trends and others will lead to the increasing adoption of optical communications technology, including optical fiber and the transceivers that are required wherever fiber is installed. The performance of these optical networks will always be improved by using the highest quality transceivers. Cinch, with a long history of designing and manufacturing rugged transceivers, can work with you to find reliable standard or proprietary transceiver solutions that maximize performance even in the harshest environments.

View Cinch’s Full Line of Optical Connectivity Solutions

View Products